Safety glasses, combined with a darkening helmet, will protect your eyes from arc flash. A welding helmet will protect your ears, neck and face from debris and slag. Safety should be the biggest priority when welding, no matter which process you choose. More expensive than TIG, MIG or stick welding.Filler metal can be applied at high speed.Easier to learn than stick welding and TIG welding.No need for a shielding gas, making it perfect for outdoor welding.Can be used in all positions with the right filler metal.This internal shield protects the weld pool, and the wire provides filler metal, which is heated and then drips to form a weld between the two metal work pieces. In flux core, the inner core of the wire consists of materials that create purifying agents and shielding gas when the welding arc is struck and heated. The shielding gas is fed from the cylinder to the welding gun, protecting the welding wire from any toxins that would jeopardize the weld. In MIG welding, a separate gas cylinder is hooked up to the welder. What sets flux core apart from MIG welding is how the filler metal is protected.

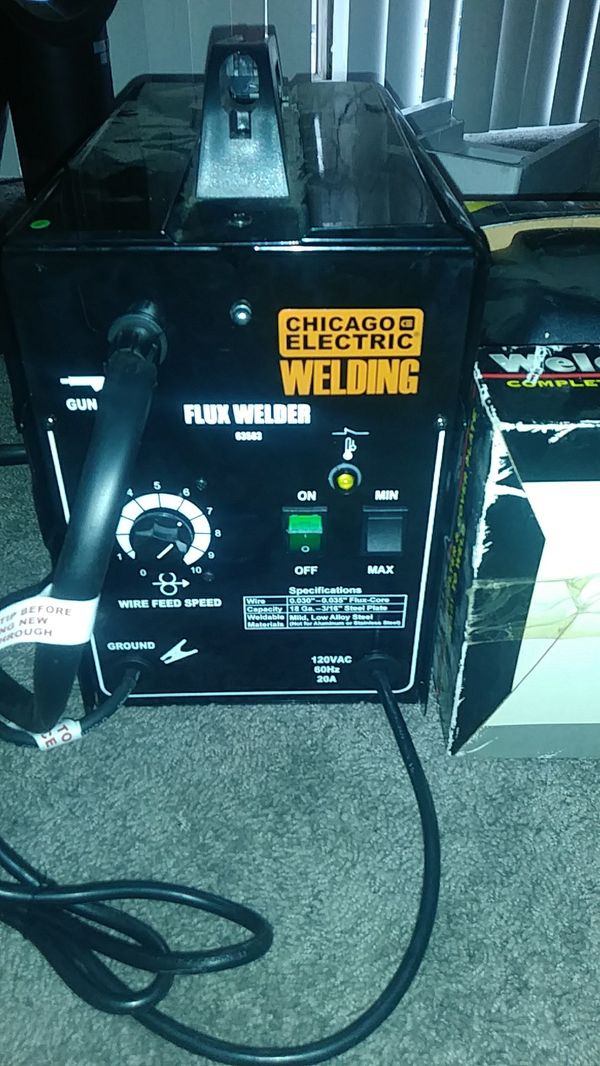

How Flux Core Welding WorksĪ wire is fed through the welder and the welding gun. You also need spools of welding wire, which is fed through the welding gun. You just need a flux core welder, a welding gun, and your metal work piece, which can be either sheet metal, tubing or whatever you need to weld. You don’t need a gas cylinder because the shielding gas is in the core of the welding wire. One of the best parts of flux core welding is the small amount of required equipment. Learn about the basics of flux core with Blain’s Farm & Fleet. Flux Core Welding Equipment If you’re going to be welding outdoors, or joining two pieces of thick metal, flux core welding may be your best option. Flux core can be used with a variety of metals, including stainless steel and some nickel and steel alloys. There are many advantages to using flux core welding, most notably its ability to be used in all positions when equipped with the right filler metal. Learn the basics of flux core welding with Blain’s Farm & Fleet.įlux core welding, also known as flux-cored arc welding or simply “FCAW,” is a type of wire feed welding.

0 kommentar(er)

0 kommentar(er)